- Home

- About Us

-

Products

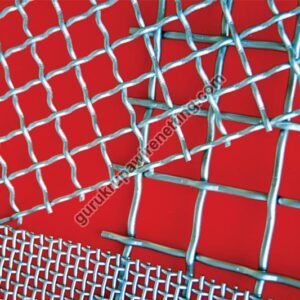

- Wire Mesh

- Security Fences

- Gabions

- Security Fencing System

- Razor Wire

- Barbed Wire

- Welded Mesh

- Gabion Box

- Perforated Metal Sheets

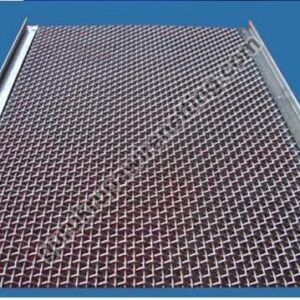

- Crusher Screen

- Gabion Mattress

- Green Facia Unit

- Welded Wire Fabric

- Fencing Accessories

- Numinous Fence System

- Rock Fall Protection System

- Construction Vibrating Screen

- Punch Tape Concertina Coils

- 358 Anti Cut Anti Climb Security Fence

- Portable Collapsible Protective Wall Basket

- Others Products

- Turnkey Solution

- Flip Book

- Home

- About Us

-

Products

- Wire Mesh

- Security Fences

- Gabions

- Security Fencing System

- Razor Wire

- Barbed Wire

- Welded Mesh

- Gabion Box

- Perforated Metal Sheets

- Crusher Screen

- Gabion Mattress

- Green Facia Unit

- Welded Wire Fabric

- Fencing Accessories

- Numinous Fence System

- Rock Fall Protection System

- Construction Vibrating Screen

- Punch Tape Concertina Coils

- 358 Anti Cut Anti Climb Security Fence

- Portable Collapsible Protective Wall Basket

- Others Products

- Turnkey Solution

- Flip Book

Building Success Together

Our Journey

Delivering quality wire mesh solutions since 1981, adhering to global standards with ISO certification.

Products

Expert engineers using advanced technology to meet the highest quality standards.

Finalizing Solutions

Reliable delivery of custom wire mesh products with a focus on client satisfaction.

Featured Products

We will send you the Best Price Possible

Welcome To Our Website

Discover Gurukrupa Wire Netting Industries

Welcome to GuruKrupa Wire Netting Industries, a leading manufacturer, supplier, and exporter of Metal Mesh Discs, Security Fencing Systems, Fences, and Accessories. We take pride in delivering high-quality products crafted by skilled engineers using advanced machinery and strict quality control. Our commitment to excellence and customer satisfaction has earned us a trusted reputation in both domestic and international markets. We strive to build lasting relationships by offering top-quality products at competitive prices tailored to our customers’ needs.

Nature Of Business

Manufacturers, Exporters, Wholesaler

Year of Establishment

1981

Name of Partner

Mr. Nainesh Soni

Number of Employees

11 to 25 People

Some Of Our Clients